FAQ

Why should people use bio-oils instead of usual mineral oil lubricants?

Bio-lubricants mitigate the negative environmental impacts of traditional petroleum-based lubricants.

Bio-lubricants are non-toxic, user and environment-friendly, extremely durable, and have better lubricity to significantly reduce the use of the oil.

High-quality bio-lubricants, such as the LUBECO™ range, also provide better anti-corrosion and protective features to prolong equipment’s life and reduce maintenance costs.

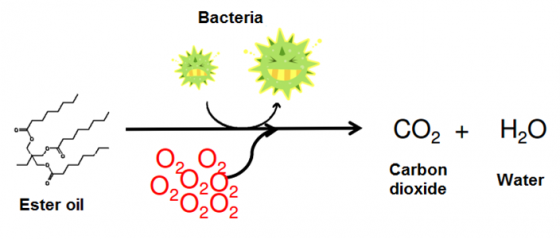

What are bio-lubricants made of and how do they "degrade" in the environment?

Most often bio-lubricants are manufactured using vegetable and synthetic ester base oils and special additives.

When released in a natural environment bio-lubricants decompose into elements of water and CO2.

How long do bio-lubricants last, compared to mineral oils?

The typical lifetime for hydraulic oils, gear oils, and universal greasing oils depend on whether they are mineral, vegetable, or synthetic based:

- Mineral hydraulic oils - up to 2500 operating hours

- LUBECO™ Synthetic hydraulic oils - up to 5000 - 8000+ operating hours

The same formula applies to our gear oils and universal greasing oils.

For Chain & Bar Oils, Saw Guide Oils and other “total loss” lubricants the lifespan is not measured as they are dispersed into the environment.

However, due to their higher lubricity use of LUBECO™ bio-lubricants can significantly reduce oil consumption.

Do you need to check the oil more often for contamination?

All oils are equally susceptible to contamination. Proper handling procedures regardless of type minimise the risk of contamination.

Need more information?

Contact us please for additional information e.g. request of MSDS etc.

We will reply to you as soon as possible.

HIGH-PERFORMANCE BIO LUBRICANTS

HIGH-PERFORMANCE BIO LUBRICANTS